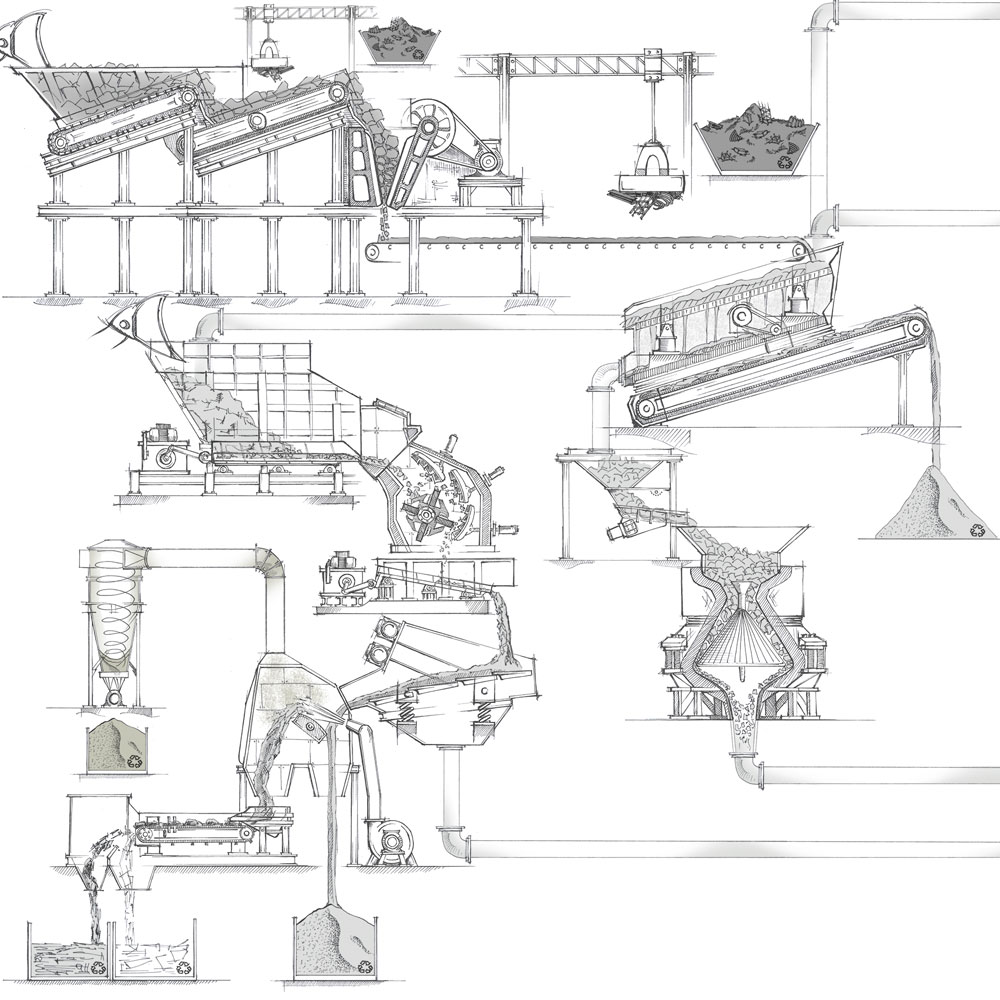

Recycling and crushing

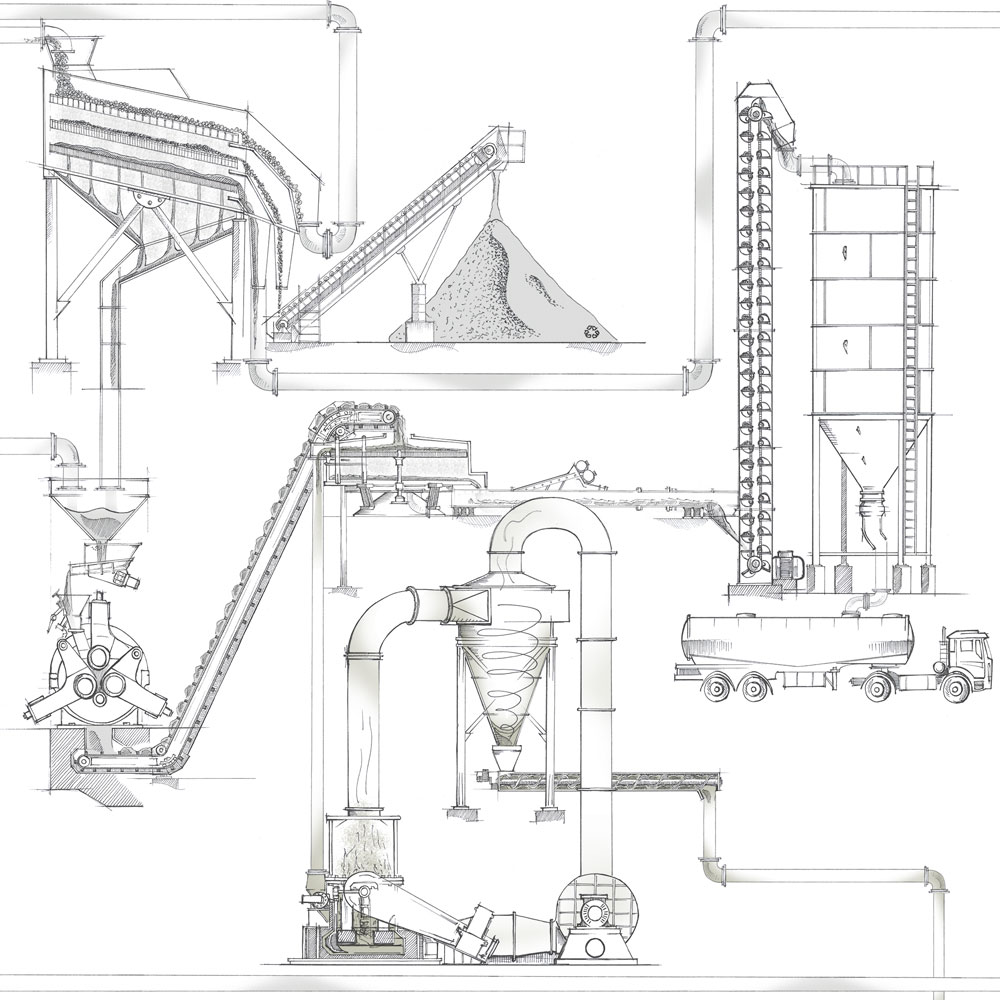

Transport, screening

and grinding

and grinding

Cullet selection

with drying

and cooling

with drying

and cooling

Washing

and fines recovery

and fines recovery

Dosing and mixing

Phosphate reaction

and gas washing

and gas washing

Suction and filtration

Wastewater treatment

sludge dehydration

sludge dehydration

Energy from biomass

and cogeneration

and cogeneration

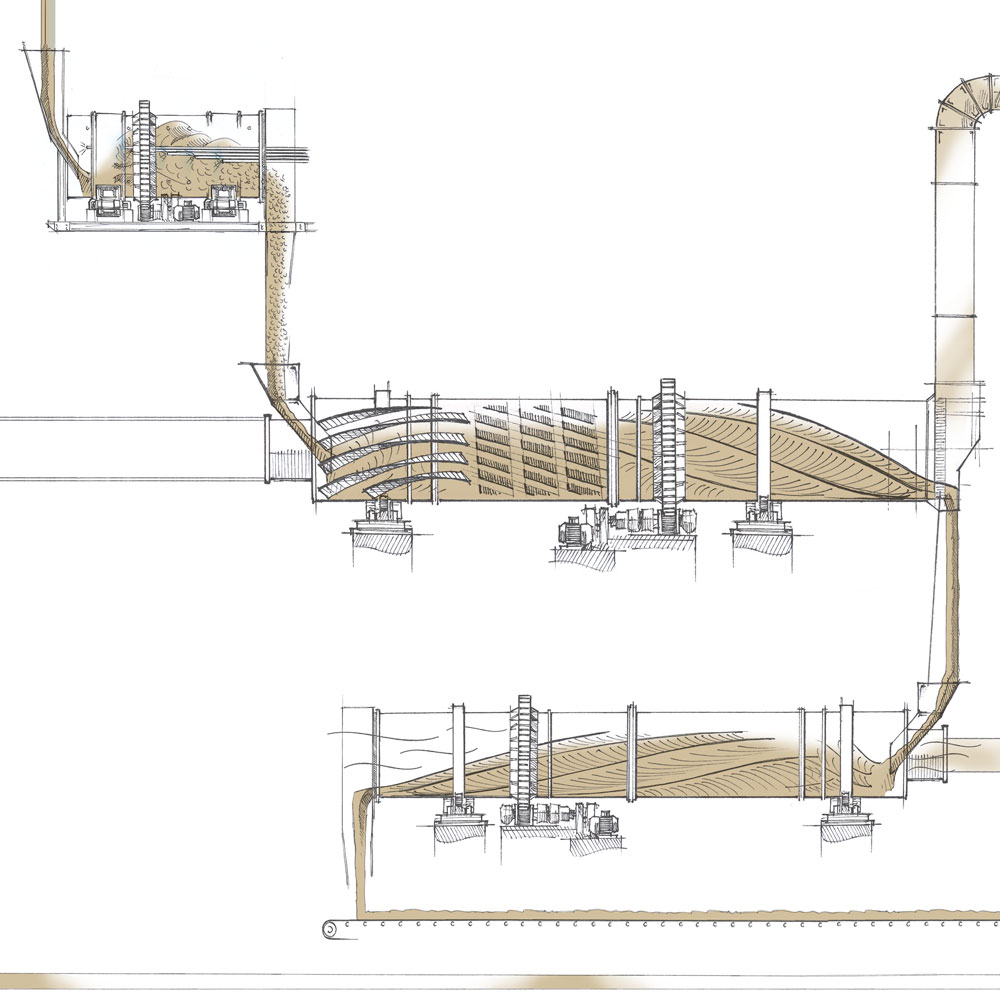

Granulation

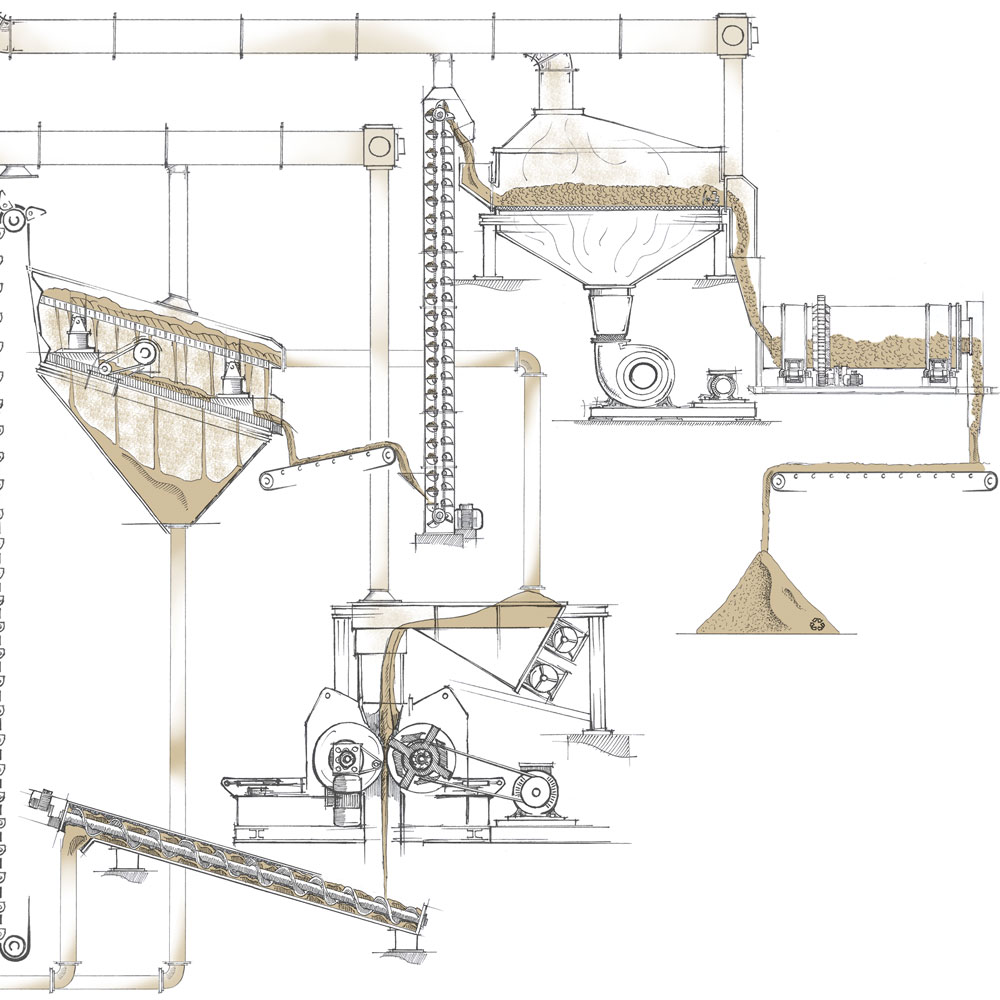

Fertilizer sieving

and stabilization

and stabilization

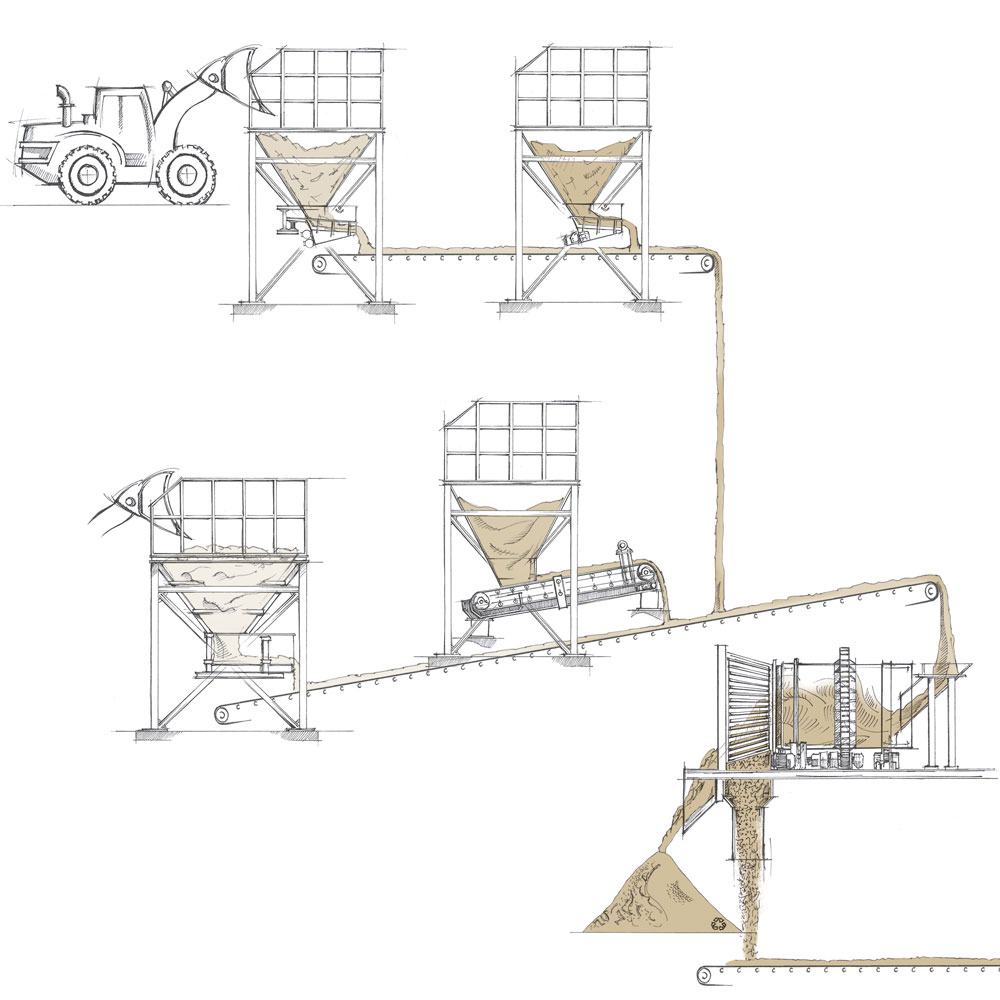

Recycling and crushing

The recycling process converts waste into resources thus saving on raw materials and energy.

In agreement with the customer, we define: type and composition of waste to be recycled, hourly input flow, type, quantity and technical features of the output products, and if the materials need to be crushed, their main characteristics, like hardness, abrasiveness, homogeneity, final granulometry etc. which will need to be considered for the crushing process. After defining the industrial process, together with the client, we will choose the machines and we will proceed to designing and constructing the recycling plant.

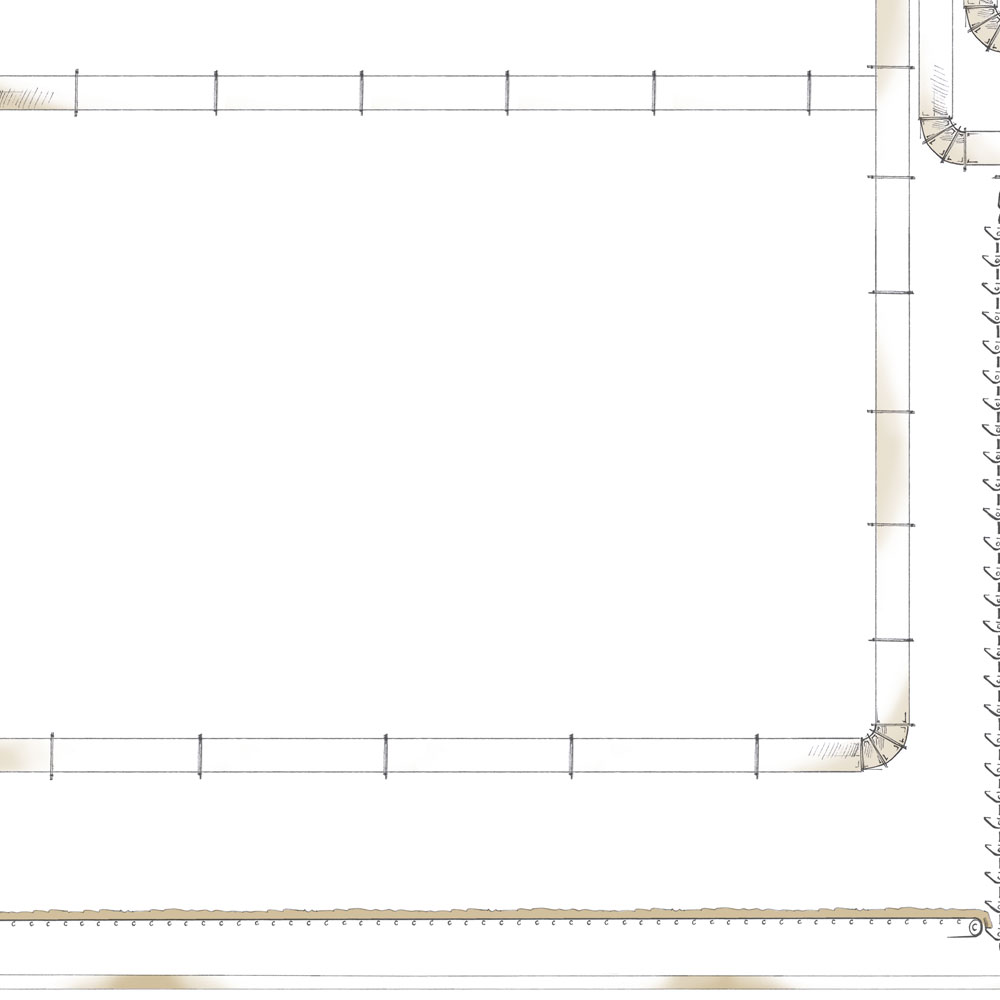

Transport screening and grinding

Mechanical conveyors are often taken for granted, as their performance characteristics are seemingly obvious and simple. This is not the case because choosing a conveyor entails a deep knowledge of the fundamental laws of mechanics and the basic flow properties of the bulk material being conveyed.

We design, manufacture and install conveying lines for bulk materials made up of belt conveyors, vibrating conveyors, bucket elevators, screw conveyors, standard chain conveyors and special chain conveyors for all industrial processes.

Conveying lines are always "tailor made products" that require a specific design and conception. From deciding on size, layout, design and interconnectivity between the machines, we then install and start-up the transport line.

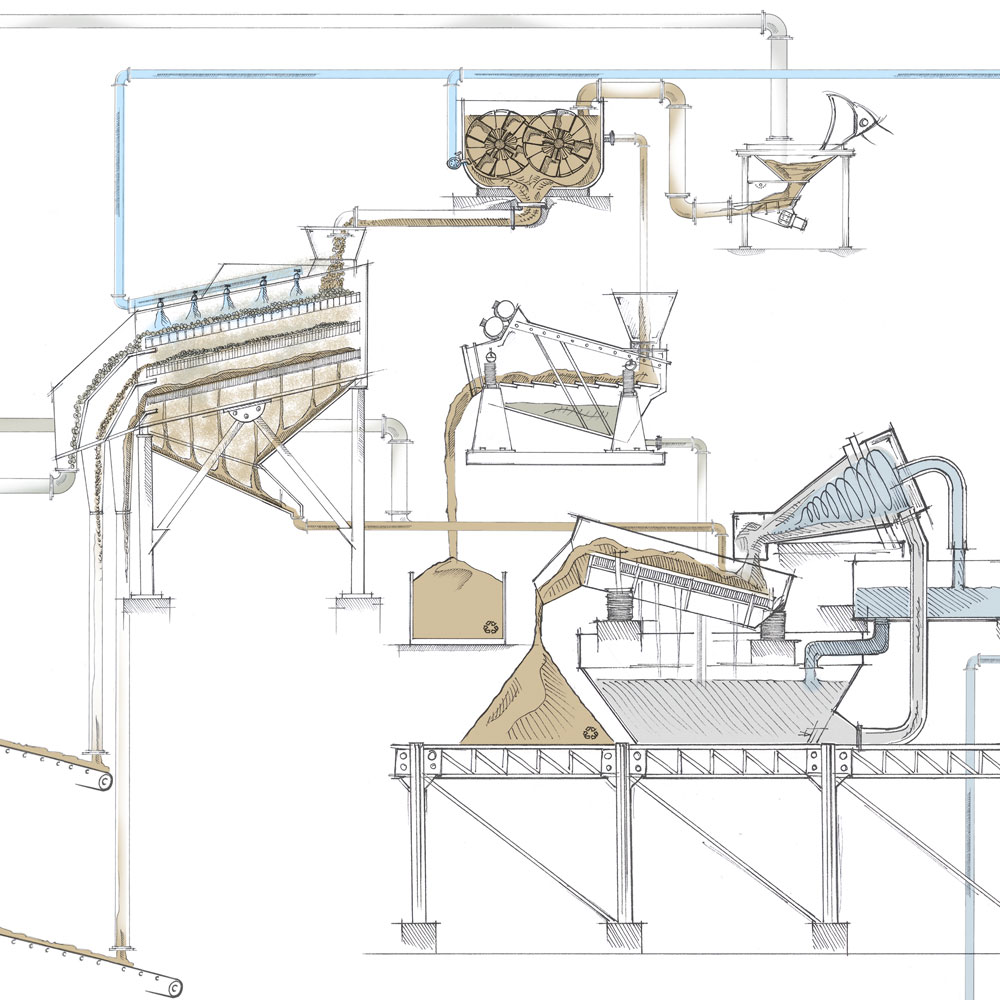

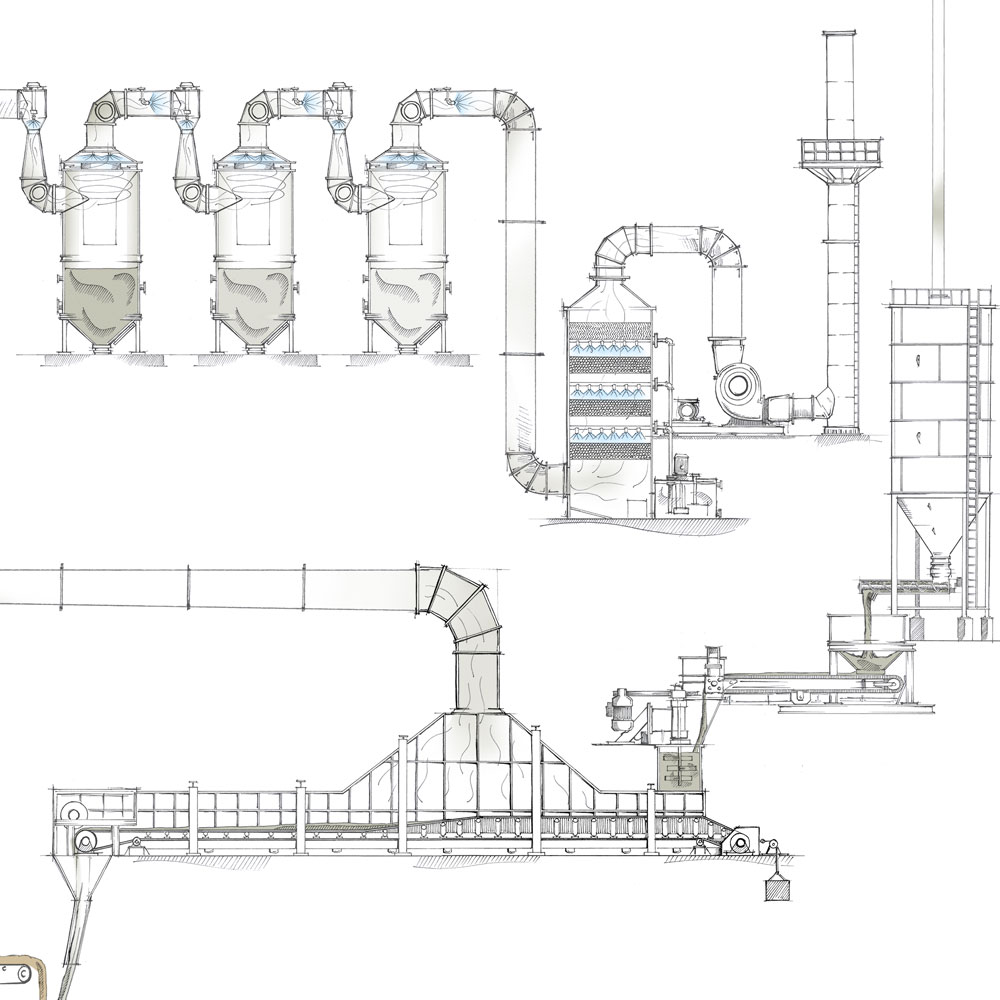

CULLET SELECTION WITH DRYING AND COOLING

We design and construct cullet selection plants by using the best machines for the treatment of glass on the market in a functional and highly effective lay-out. With a project that suits the needs of the customer, we see to the detailed designing and the building of all conveyors (belt conveyors, bucket elevators, vibrating conveyors, screw conveyors, chain conveyors and special chain conveyors); connections between the process machines; suction and filtration plants (bag filters, cyclones plenum, pipes, chimneys); dryers, and coolers, to obtain the highest quality cullet, ready for the glass factory furnace).

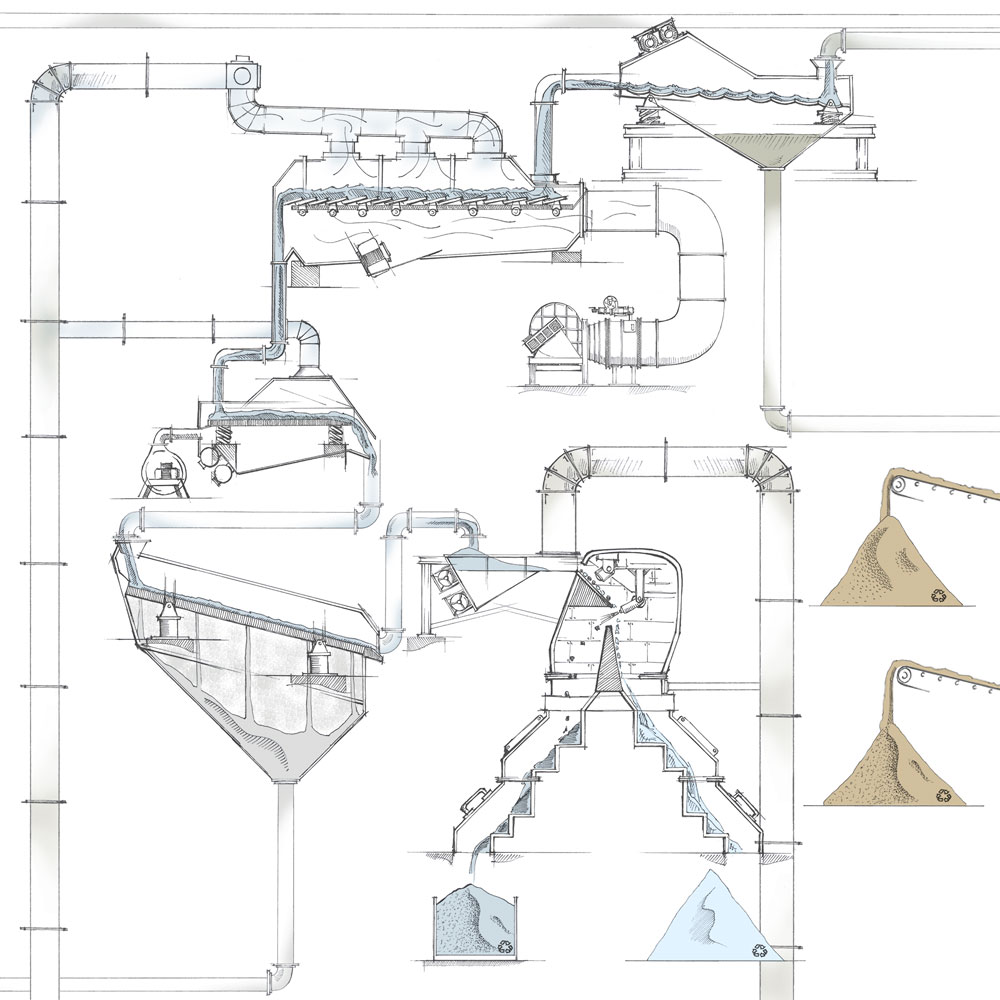

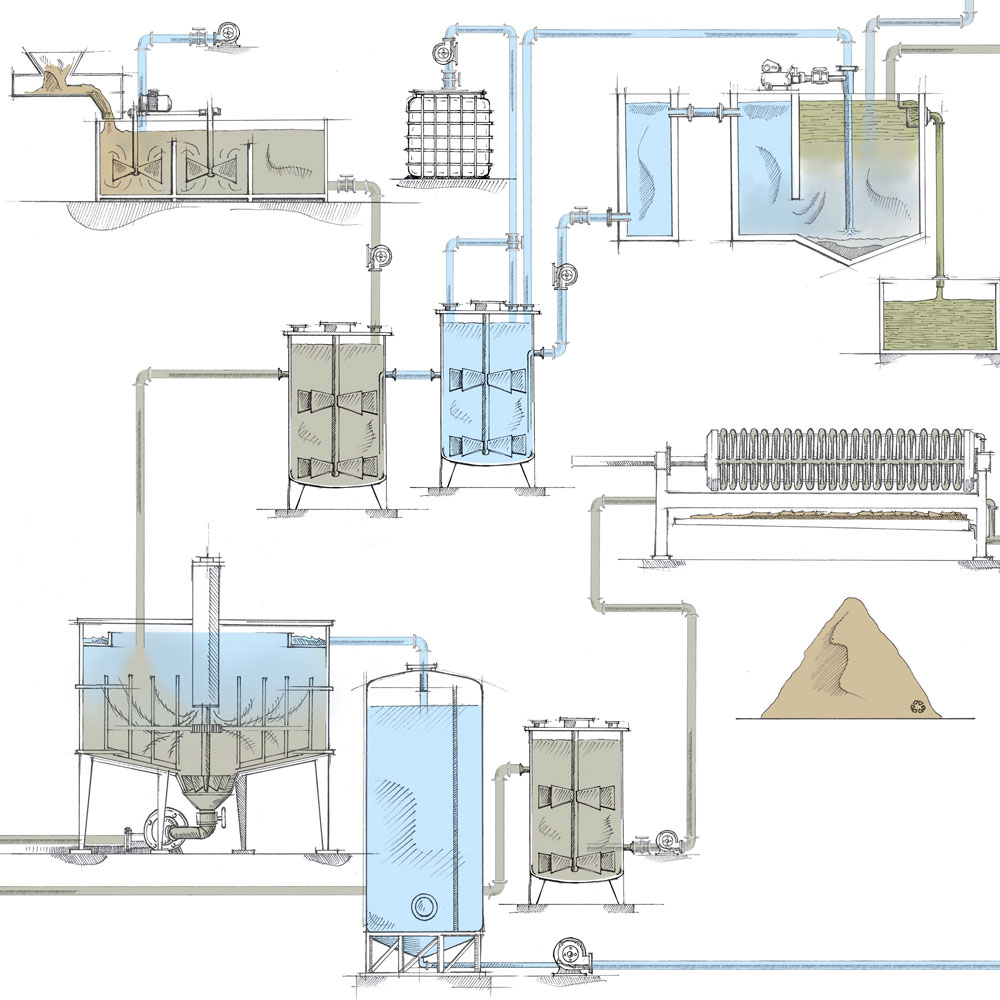

Washing and fines recovery

When the material is dirty and needs to be washed before use, we design, build and install complete systems of washing and selection. We also recover fines that are dragged away by the wash water.

Washing systems, and fines recovery groups, are designed not only according to the product to be washed but also according to what kind of material needs to be washed away.

Dosing and mixing

We design, build and install systems for dosing and mixing many different products.

The system we adopt depends essentially on the physical characteristics of the materials to dose and blend: for example, for free-flowing materials for which dosing must be precise, we use electromagnetic feeders or belt feeders, which allow for good accuracy, while we adopt electromechanical feeders when precision is less important.

Phosphate reaction and gas washing

Phosphate rocks come from fossil deposits, which are the residues of prehistoric seas, and they are rich in calcium phosphate. The rocks actually found in nature are in fact inert and in order to transform the phosphate into a form suitable for the plants, we have to dissociate it from the calcium. To do this, it is necessary to reduce the rocks into very fine powders and treat them with sulphuric or phosphoric acid, in order to produce two basic fertilizers: SSP (Single Super Phosphate) or TSP (Triple Super Phosphate).

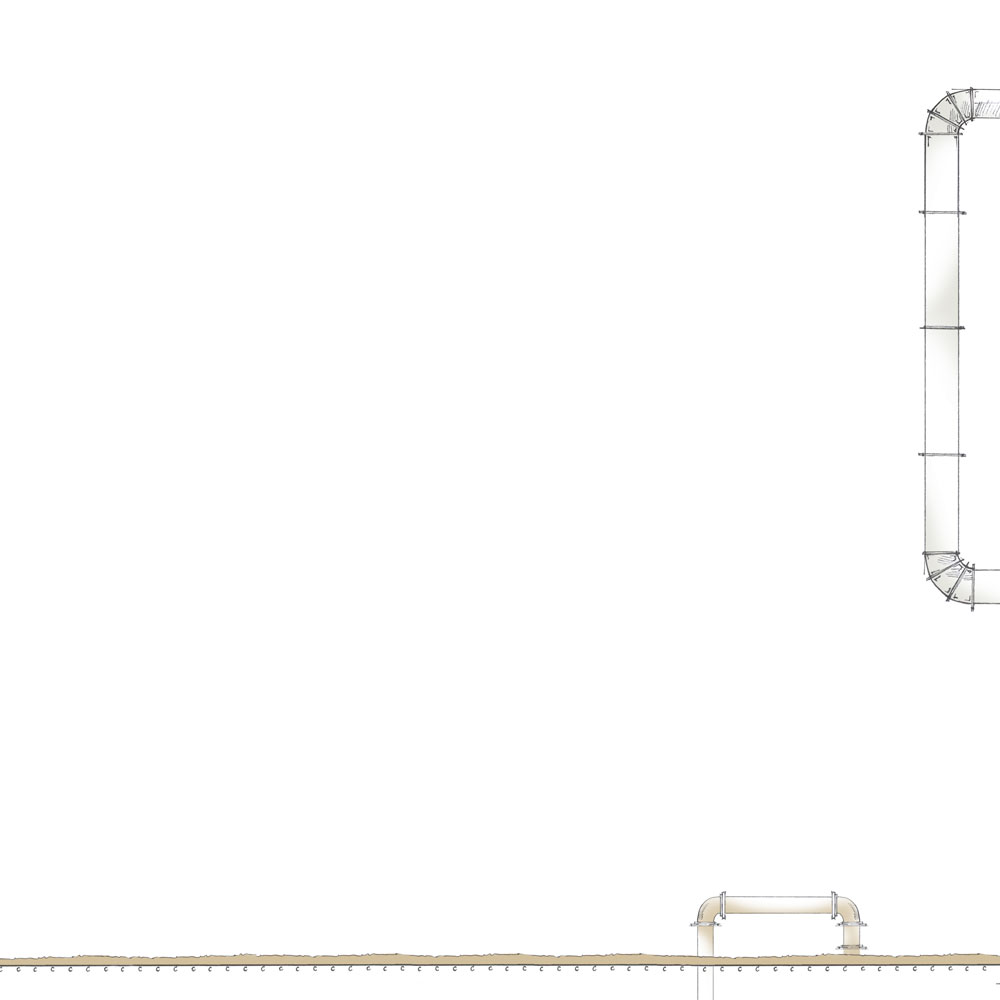

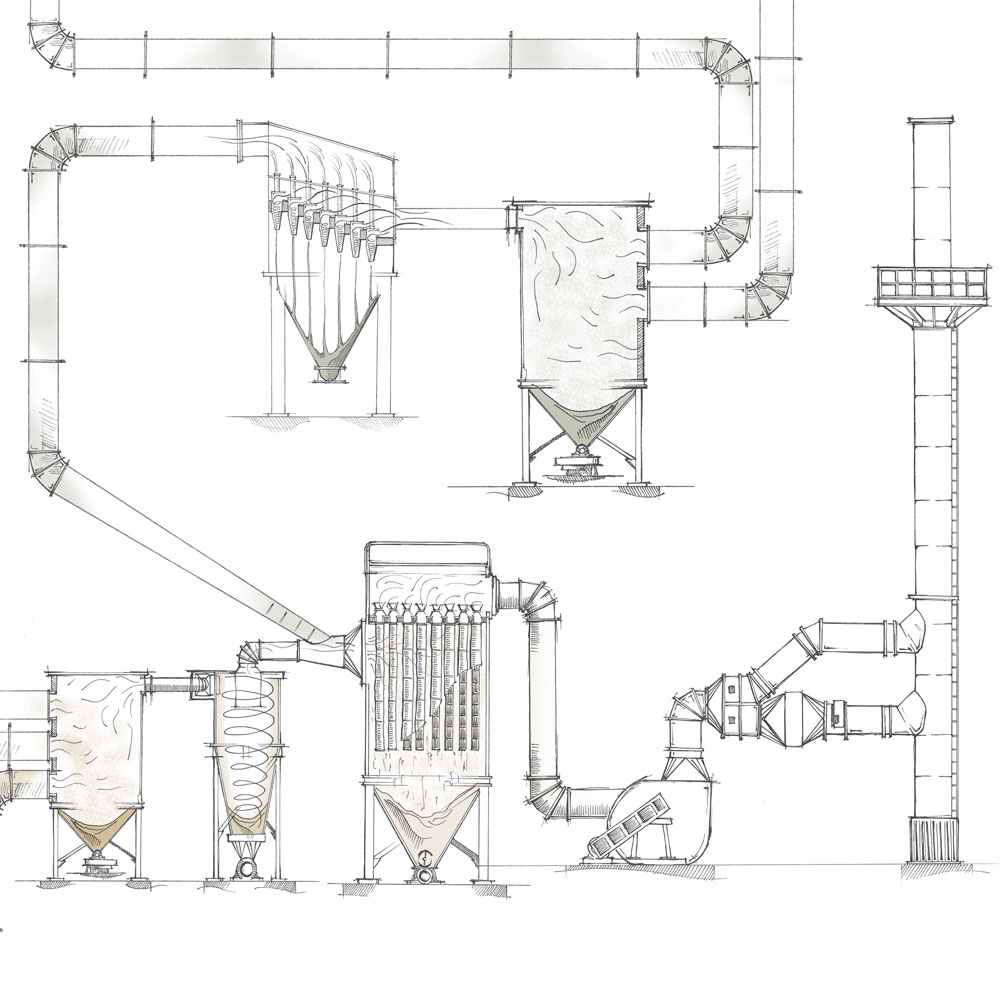

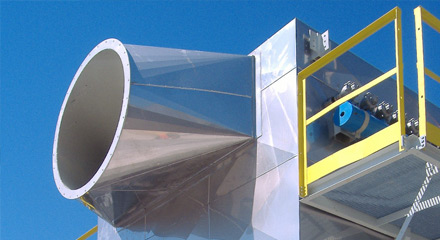

Suction and filtration

We design, manufacture and install suction systems for air and fumes, equipped with suitable filtration systems.

Our scientific approach to the problem of the suction of dusty gaseous streams of gases, takes into account the physical and chemical features of pollutants inside the sucked stream.

The suction of air with wood dust is completely different from the suction of air or fumes containing inert or fertilizing dust.

Wastewater treatment sludge dehydration

The wastewater coming from the washing of contaminated products, or simply full of mud, must be cleaned before being sent to the disposal systems or being reused in the washing process.

The wastewater treatment systems, which we design, manufacture and install, are of a chemical-physical type. Their configuration depends largely on the type of effluent to be treated.

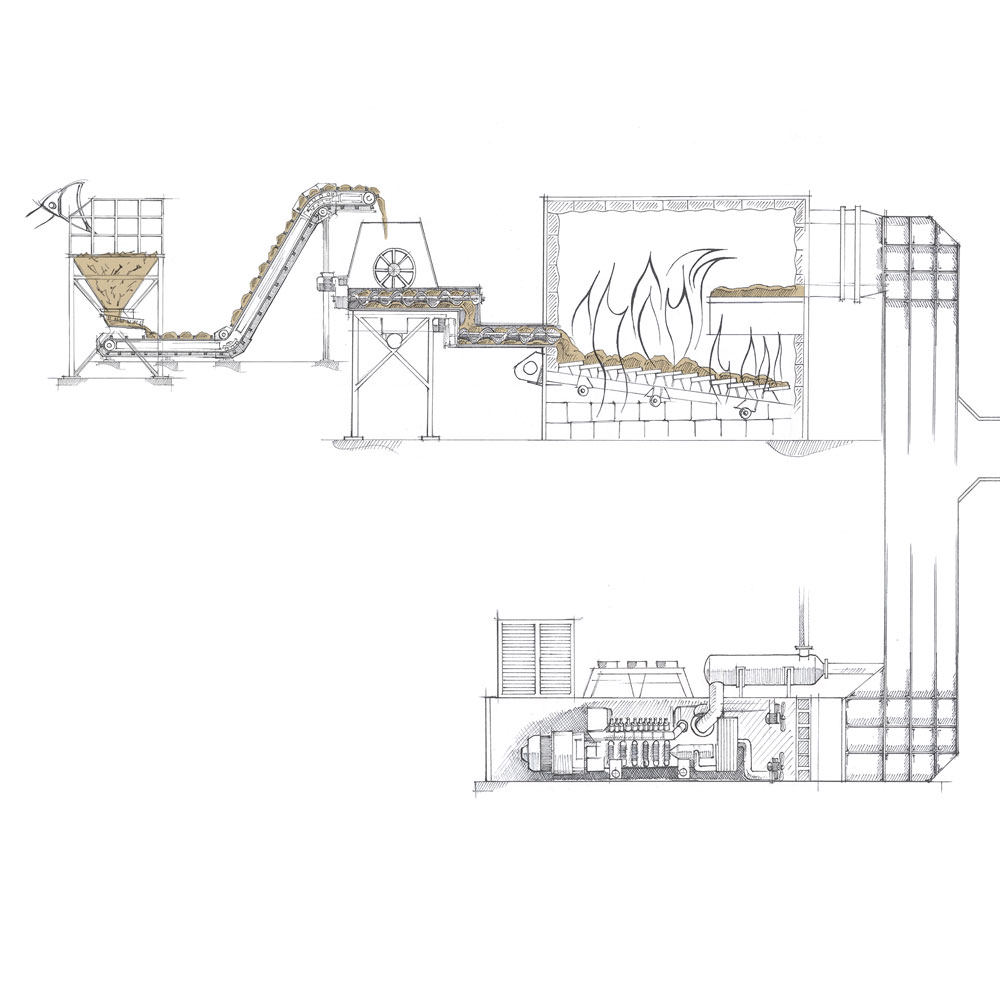

Energy from biomass and cogeneration

In the last few years, the use of biomass in the production of steam and / or superheated water has taken on an important economic role and many installations have been made. We design and manufacture accessory equipment for biomass boilers such as fume suction and filtration, biomass fuel supply and ash evacuation.

For energy saving, we design cogeneration systems for electrical energy production with heat recovery. Heat can be in the form of hot air to be used, for example in drying processes, or as hot water.

Granulation

When the simple mixing of powders or crystals is not enough and it is necessary to obtain compact granules and each of these contains all the elements of the mixture the process called granulation of powders and crystals is used.

Granulation is a process in which primary powder particles of a mixture are made to combine to form larger multiparticle entities called granules. It is the process in which we combine elementary particles by creating bonds between them using a binding agent.

Fertilizer sieving and stabilization

After cooling the fertilizer granules must be sieved according to their size so as to allow them to be scattered over the field effectively and efficiently with mechanical means. For this purpose, we study, design, manufacture and install systems that sieve the granules and pulverize those that are too large. For the sieving process we adopt vibrating screens while to grind coarse granules we use mills with articulated hammers or roller mills.