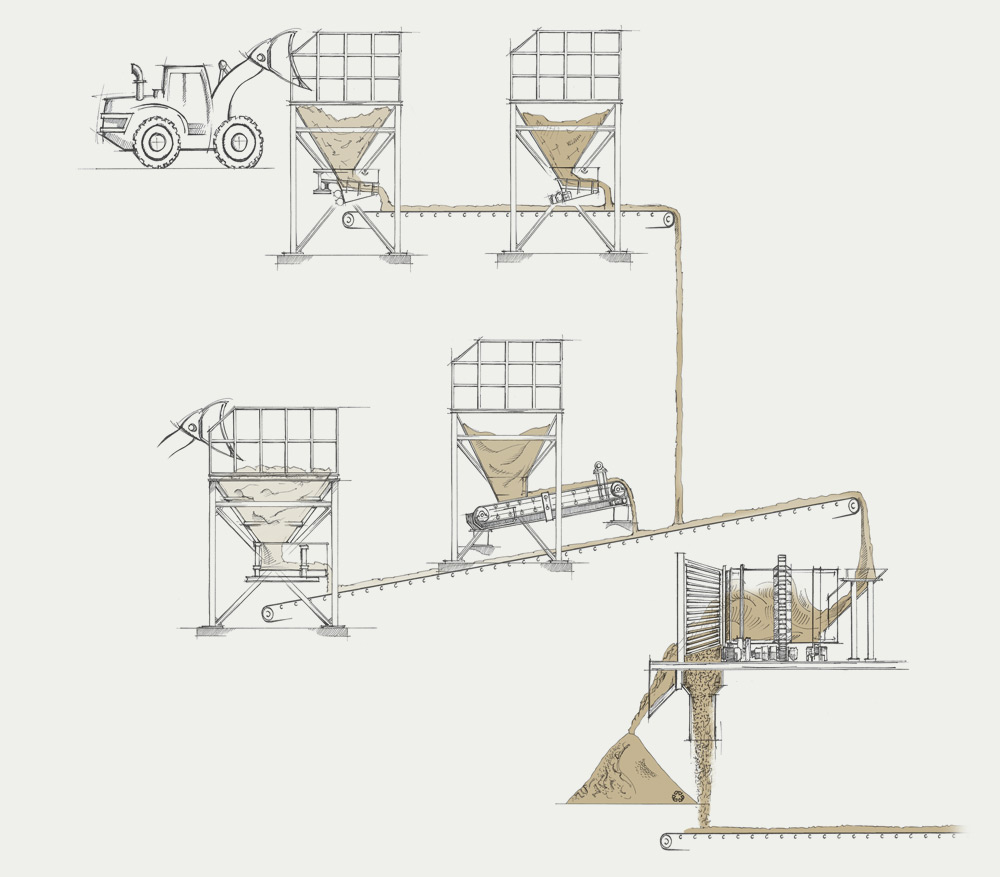

Dosing and mixing

We design, build and install systems for dosing and mixing many different products.

The system we adopt depends essentially on the physical characteristics of the materials to dose and blend:

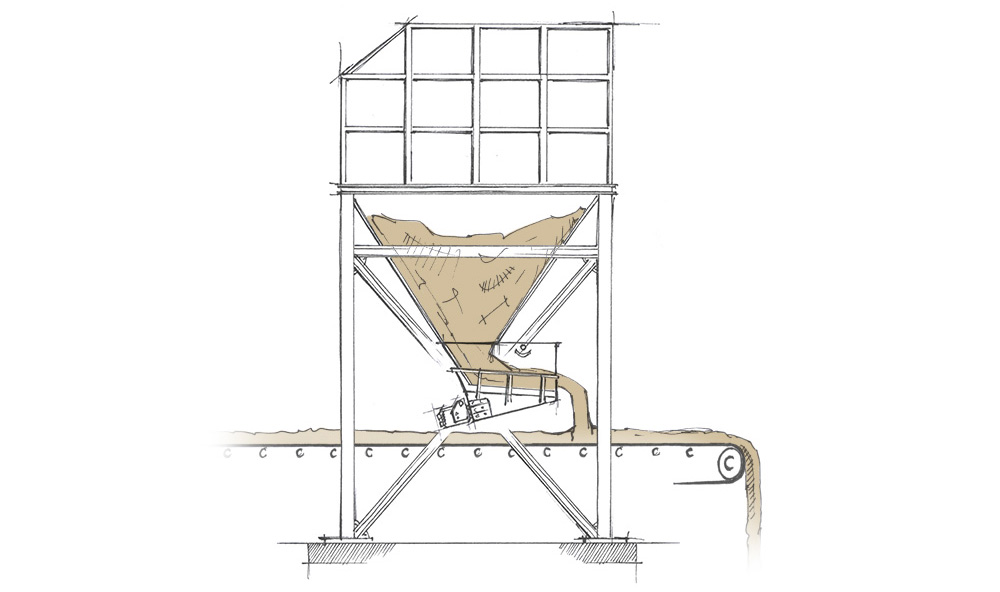

for example, for free-flowing materials for which dosing must be precise, we use

electromagnetic feeders or

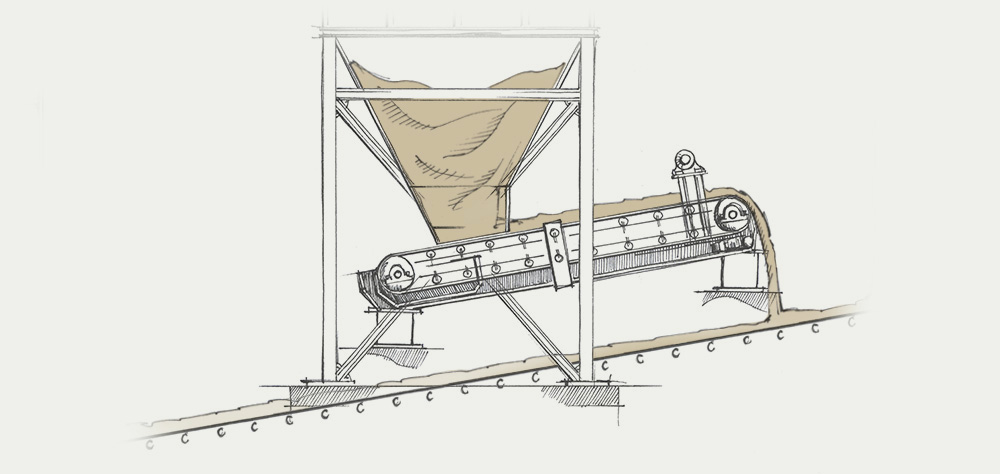

belt feeders,

which allow for good accuracy, while we adopt

electromechanical feeders when precision is less important.

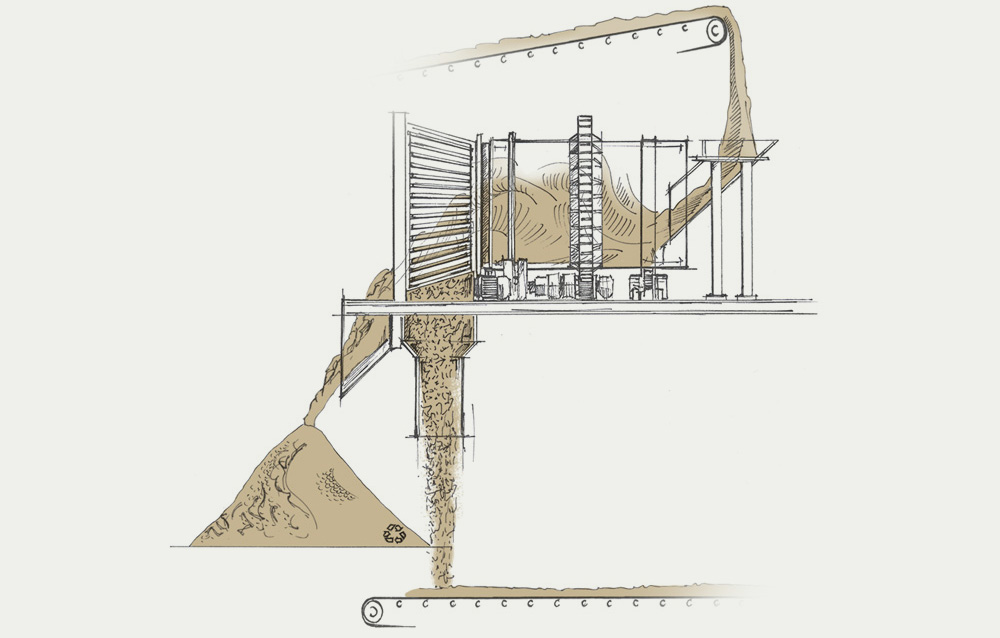

We build both continuous and discontinuous systems for dosing and mixing.

Whenever possible we design continuous mixing plants consisting essentially of belt extractors,

which ensure very high accuracy thanks to electronic weighing,

and of

continuous rotary mixers which have much lower energy consumption compared to batch mixers.

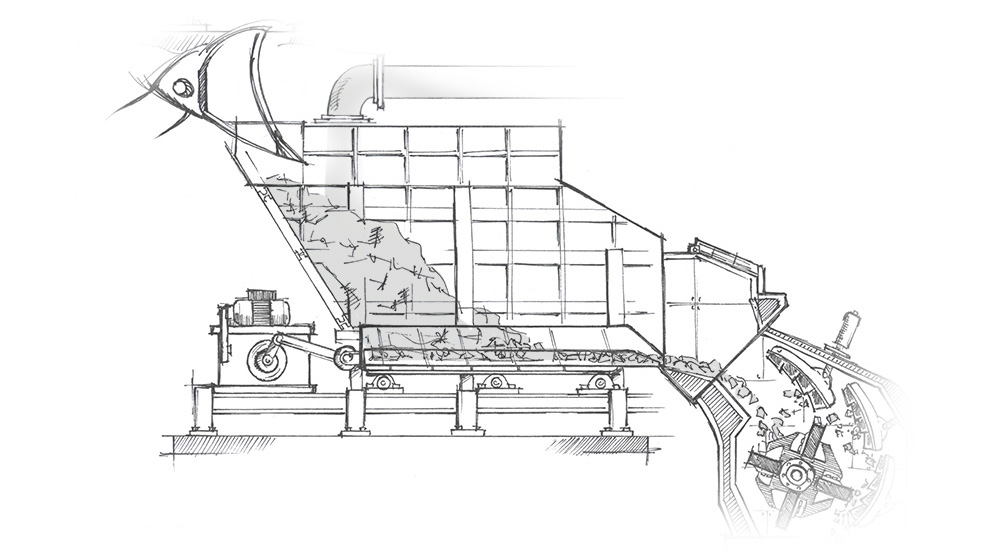

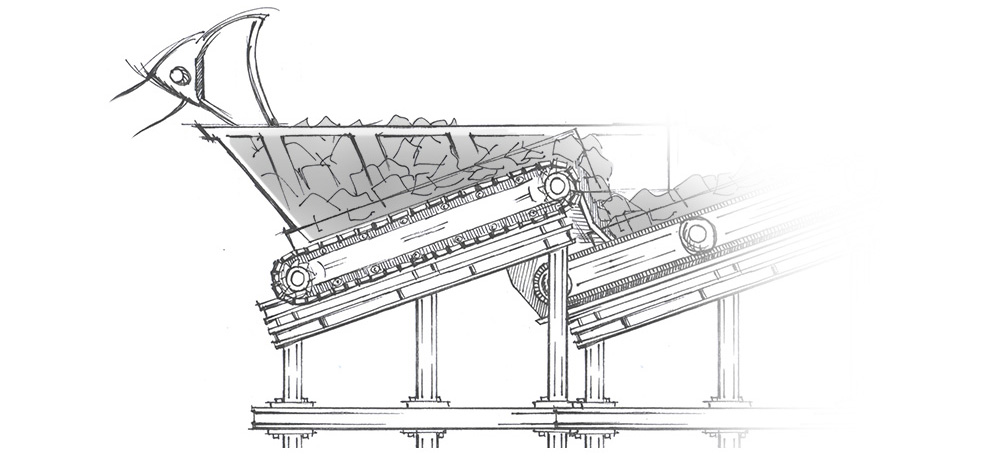

For the most challenging applications (e.g. aggregates that are highly adhesive or under impact mills)

we adopt

reciprocating plate feeders with a mechanical or hydraulic drive.

We have designed and constructed reciprocating plate feeders of different sizes

and we always combine reliability in dosing with machine robustness.