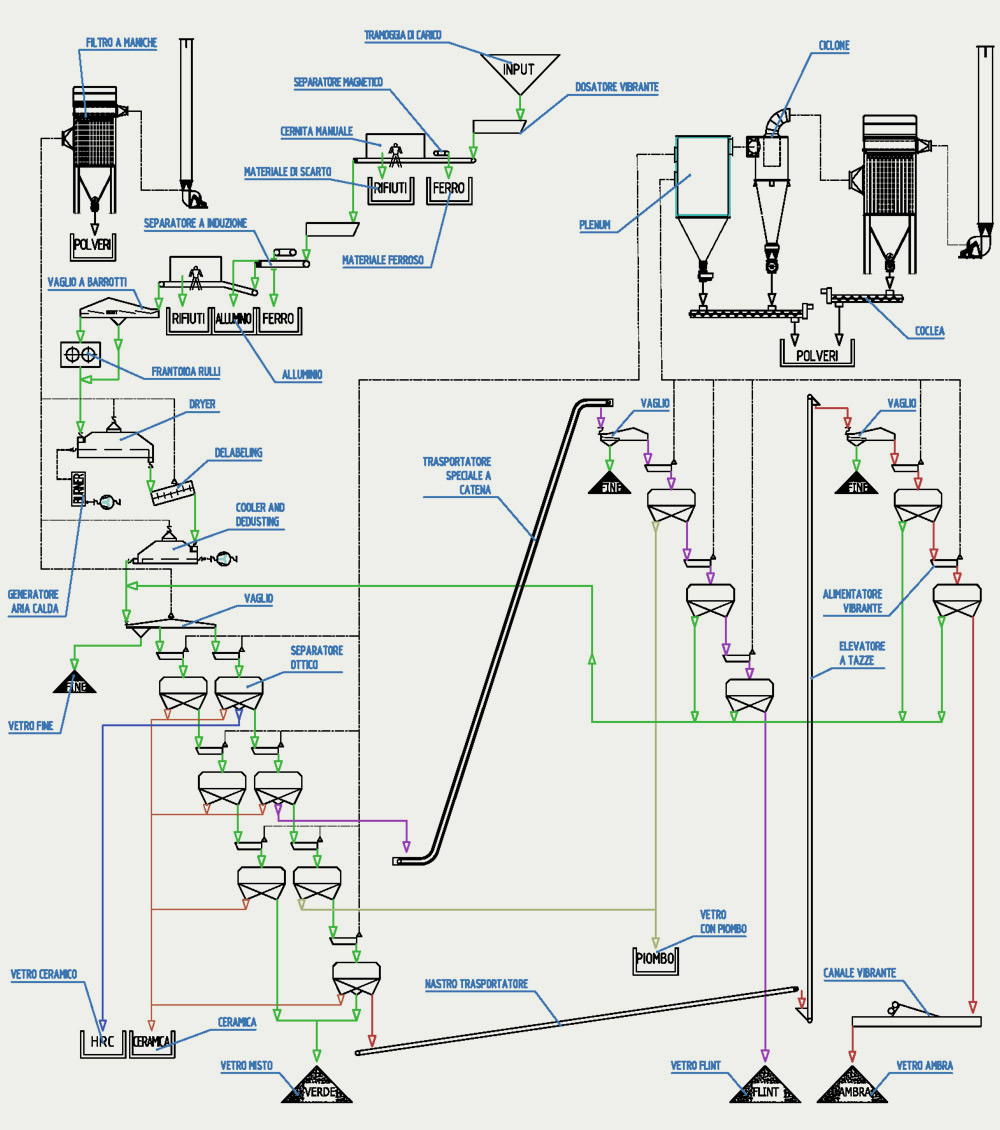

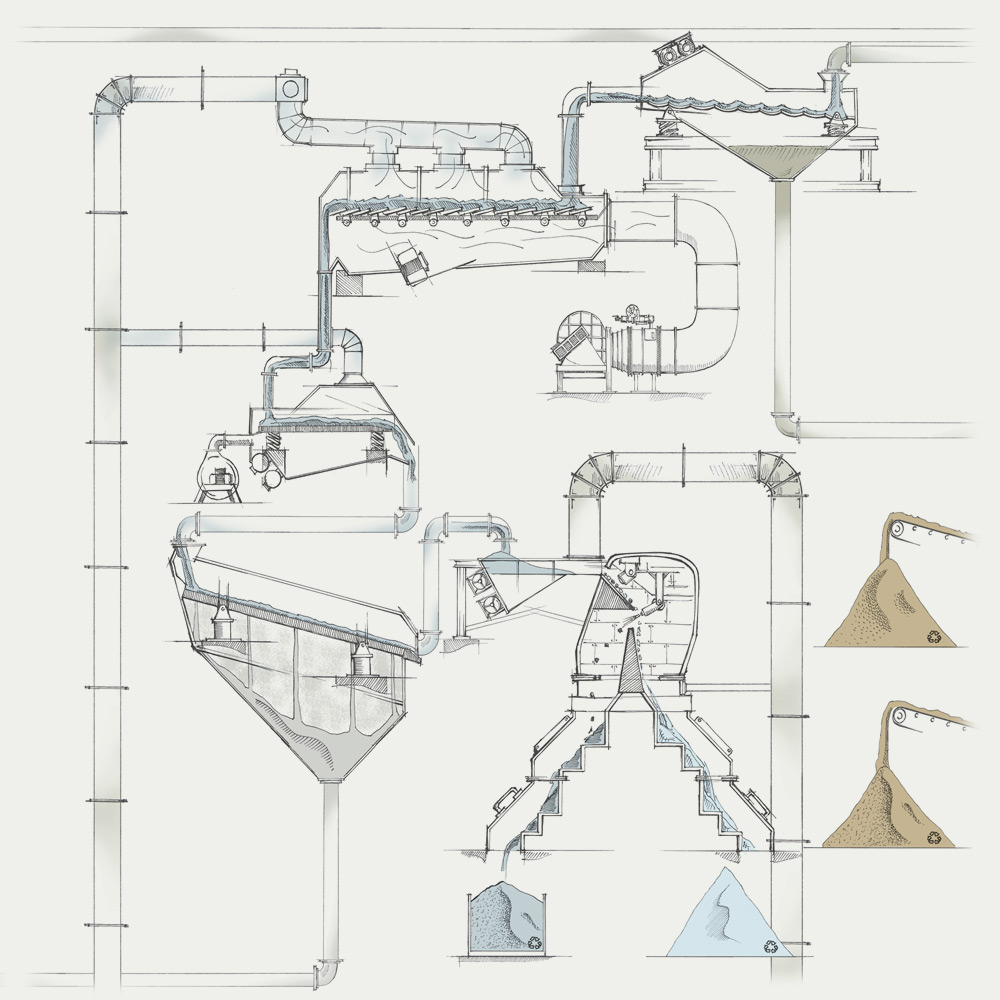

Cullet selection with drying and cooling

We design and construct

cullet selection plants by using the best machines

for the treatment of glass on the market

in a functional and highly effective lay-out.

With a project that suits the needs of the customer, we see to the detailed designing and the building of all conveyors

(

belt conveyors,

bucket elevators,

vibrating conveyors,

screw conveyors,

chain conveyors and

special chain conveyors);

connections between the process machines; suction and filtration plants (

bag filters,

cyclones plenum,

pipes,

chimneys);

dryers, and

coolers, to obtain the highest quality

cullet, ready for the glass factory furnace)

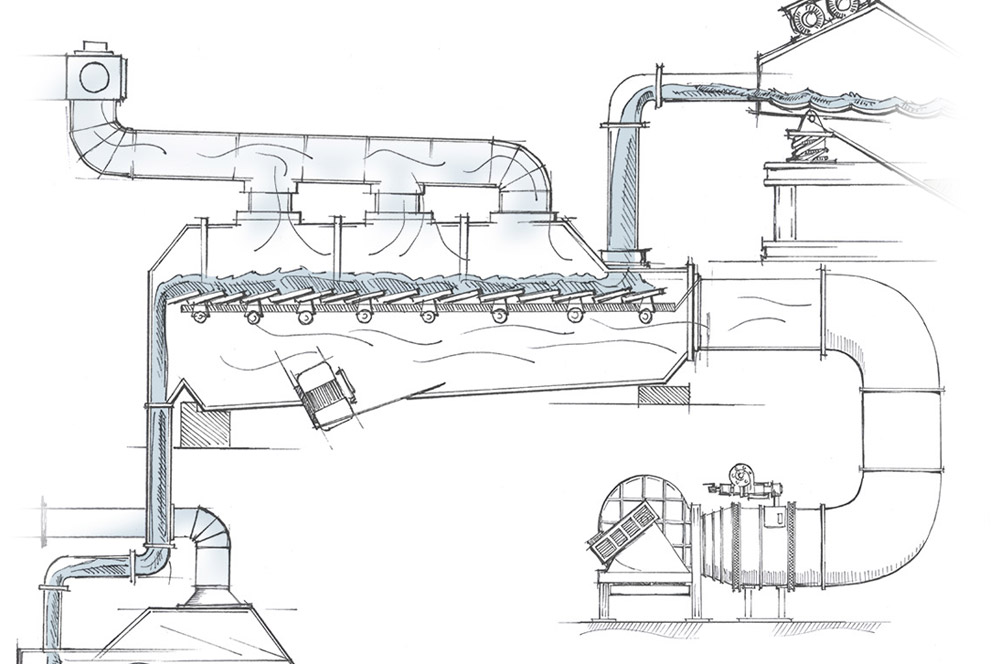

In order to get the best quality glass recycling, it is essential to have well-dried cullet with small amounts of dusts.

We design, build and install systems for drying and cooling cullet with particular attention to energy consumption in order to minimize operating costs;

Abrasiveness of the cullet in order to preserve duration of machines and connections;

Brittleness of the cullet so as to limit the production of fines and powders.

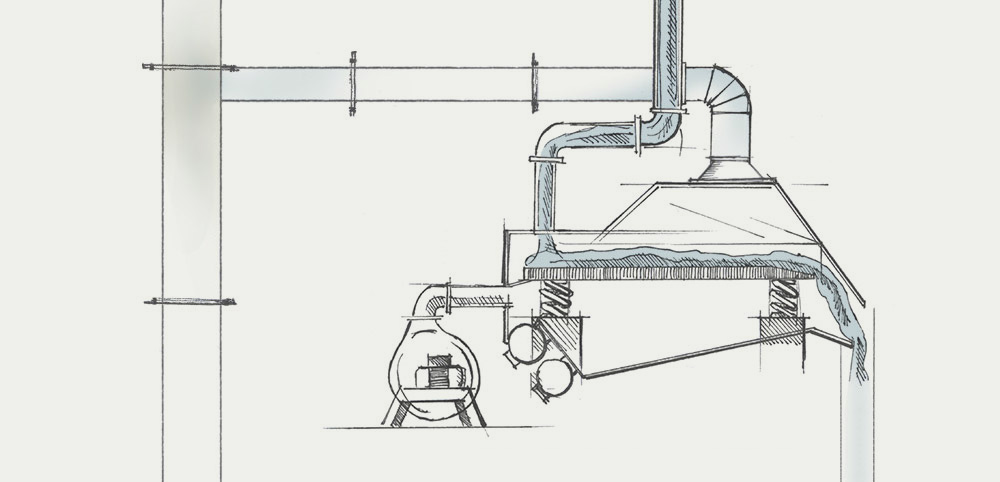

We manufacture modulating

hot air generators.

They are controlled by temperature and pressure sensors that constantly guarantee the right amount of heat to the dryer.

This ensures that only the necessary fuel is used with considerable energy saving.

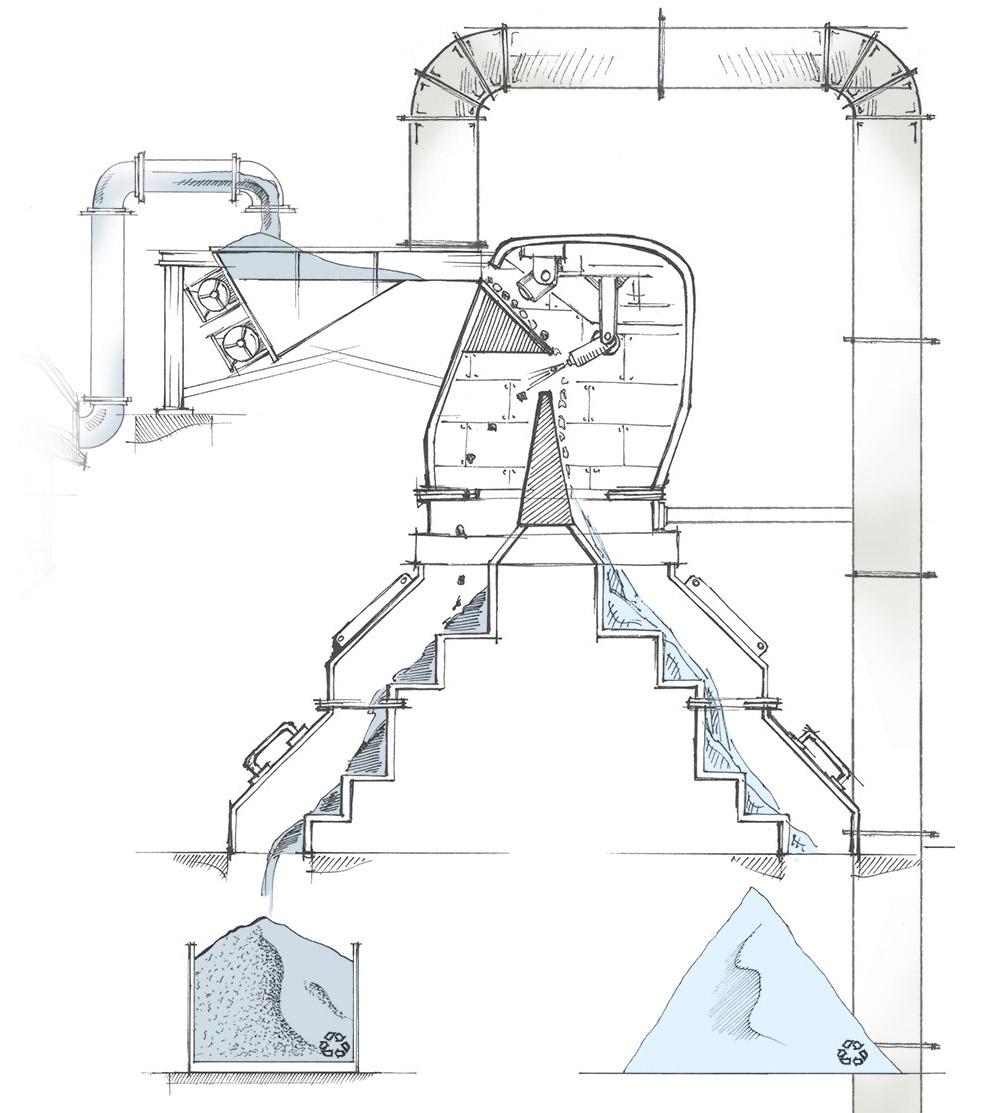

The

fluid bed coolers that we install are of a high thermal efficiency type, and, in addition to cooling,

they carry out product dedusting and the separation of light fractions.