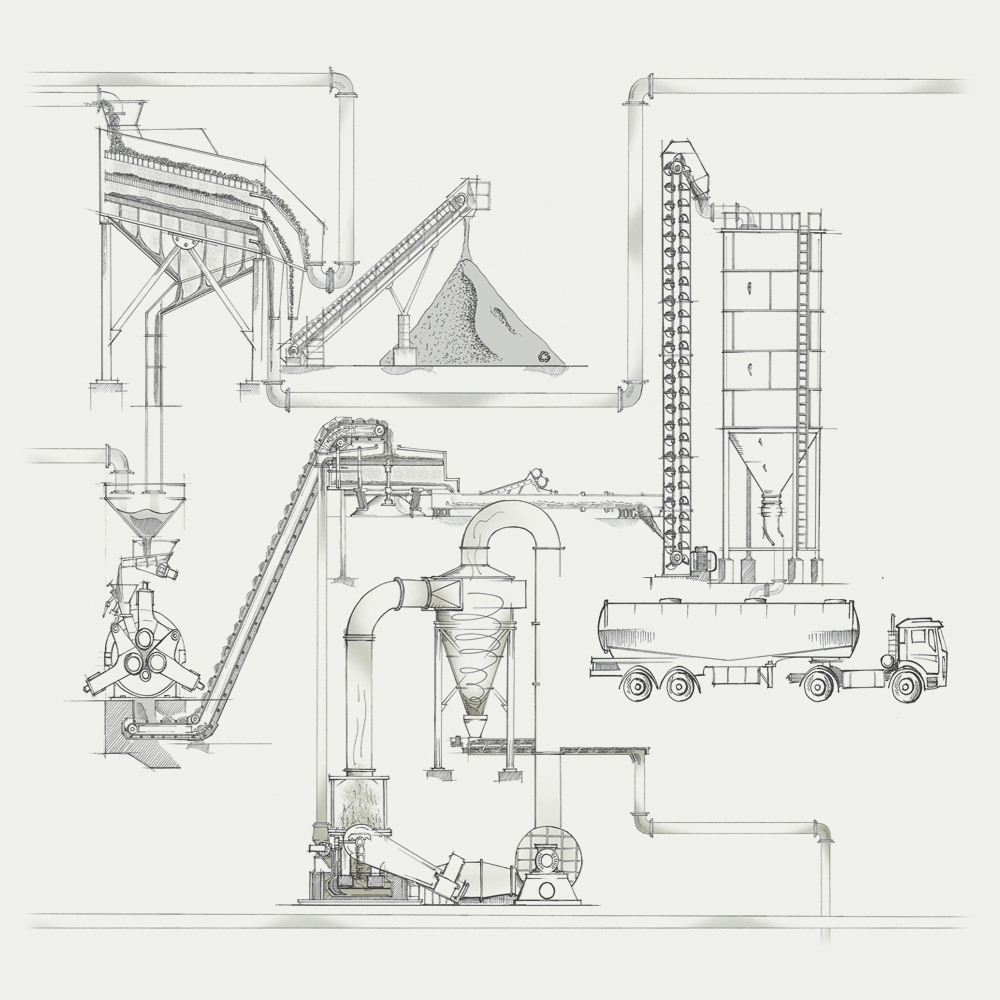

TRANSPORT, SCREENING AND GRINDING

Mechanical conveyors are often taken for granted, as their performance characteristics are seemingly obvious and simple. This is not the case because choosing a conveyor entails a deep knowledge of the fundamental laws of mechanics and the basic flow properties of the bulk material being conveyed.

We design, manufacture and install conveying lines for bulk materials made up of

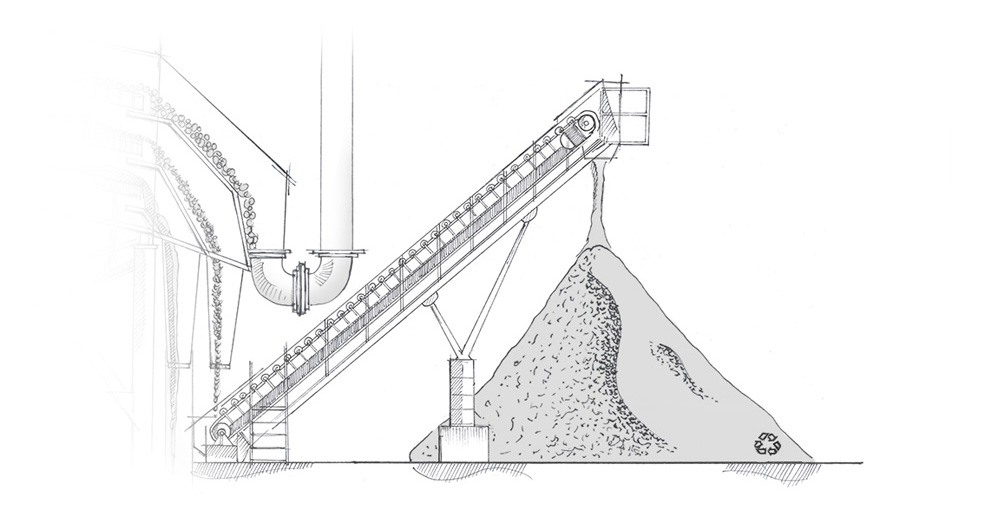

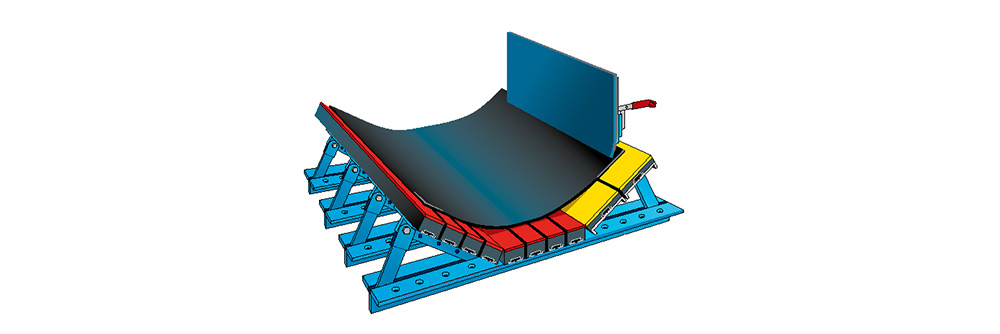

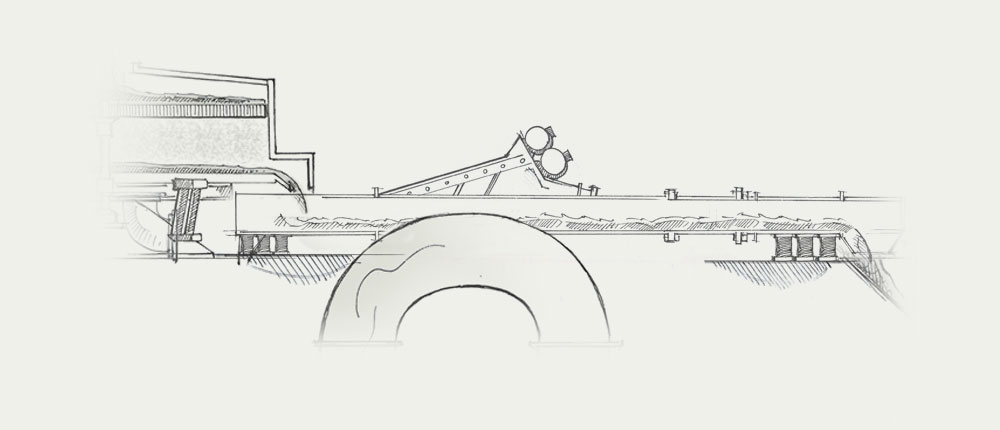

belt conveyors,

vibrating conveyors,

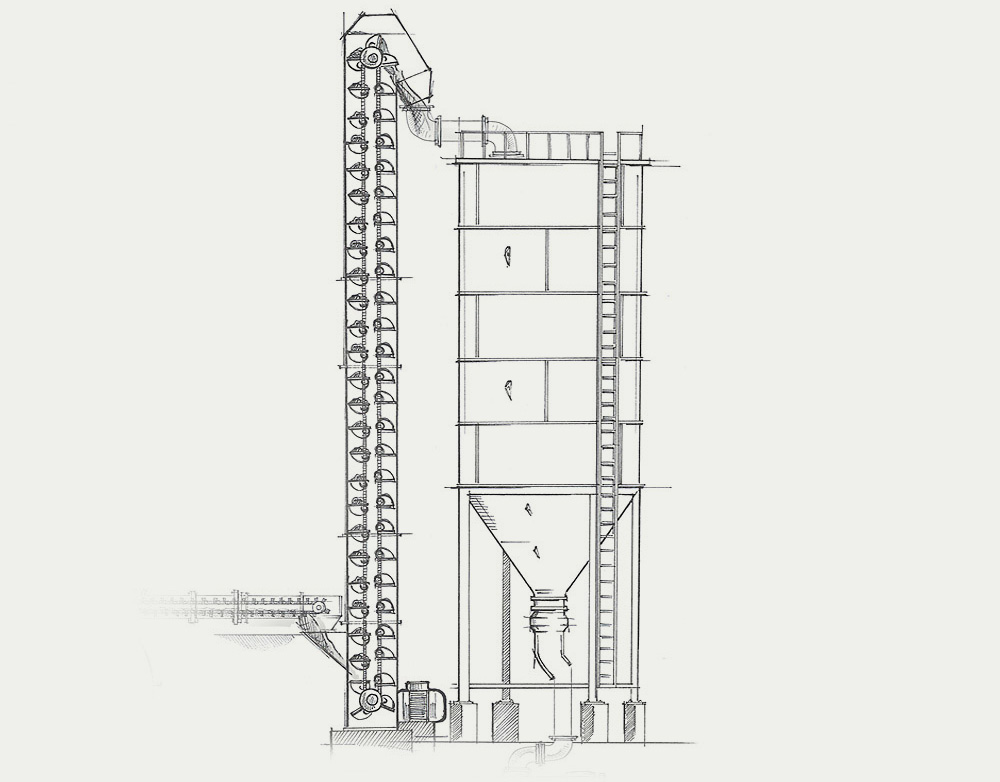

bucket elevators,

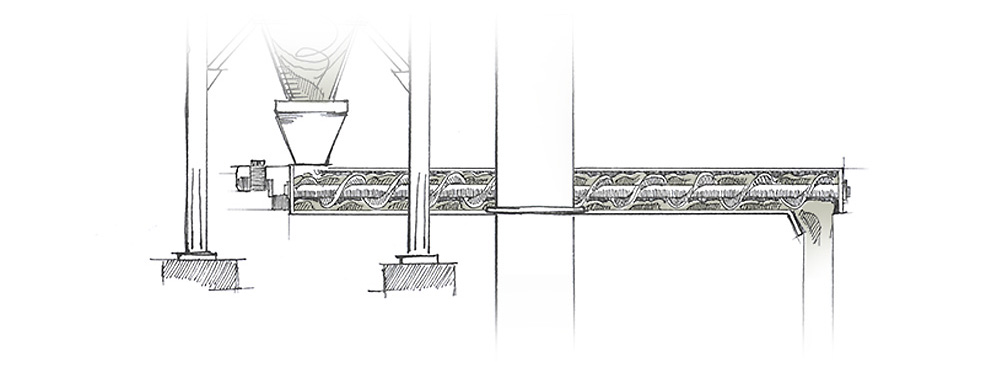

screw conveyors,

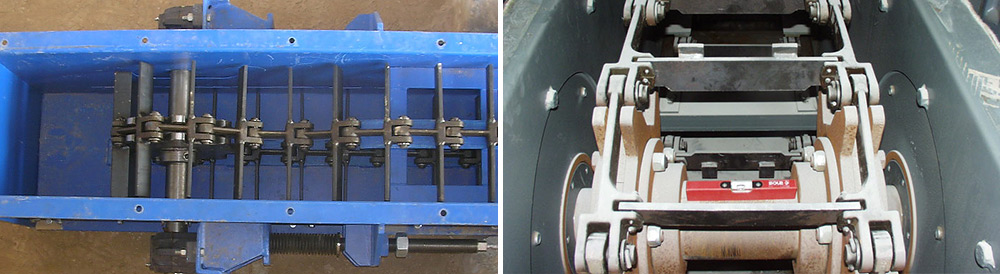

standard chain conveyors and

special chain conveyors for all industrial processes.

Conveying lines are always

"tailor made products" that require a specific design and conception. From deciding on size, layout, design and interconnectivity between the machines, we then install and start-up the transport line.

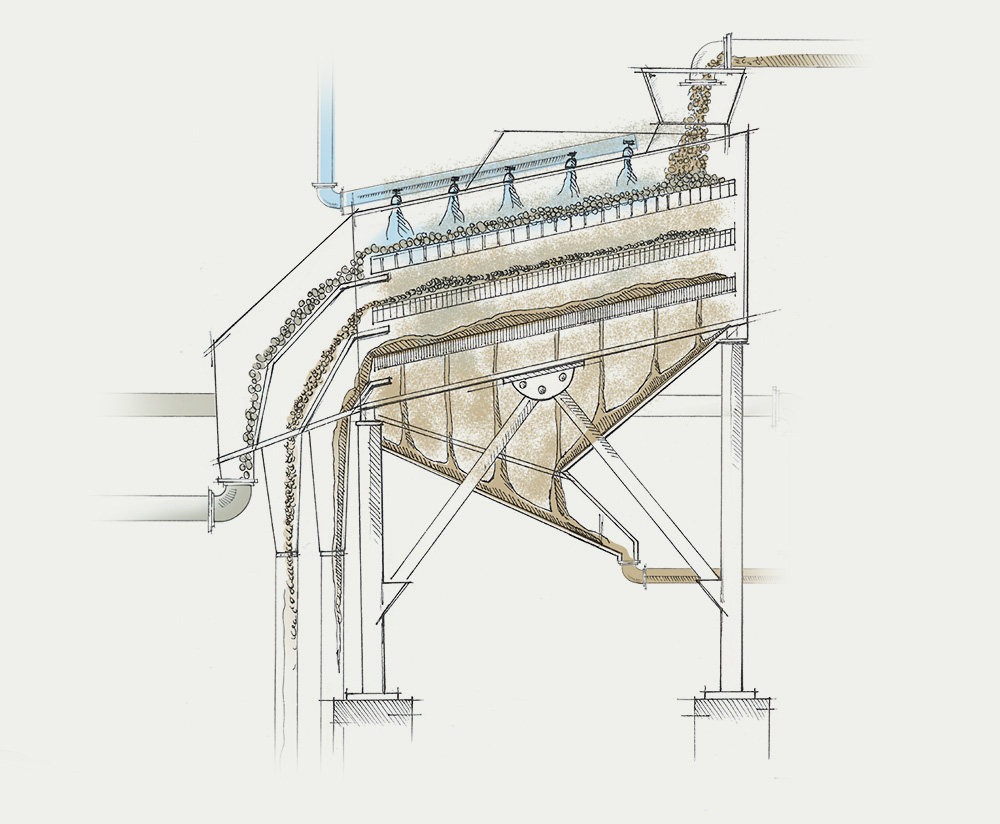

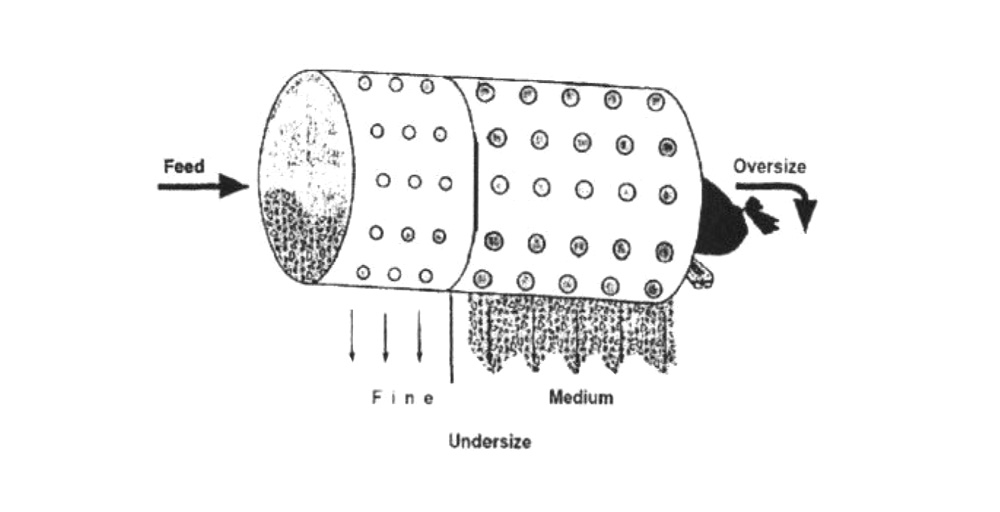

We use many different systems to sieve bulk materials and obtain classification of grain size. Depending on the material, its size and the type of selection required, we choose, together with the customer, the most suitable machines:

vibrating screens,

rotary screens, resonance screens, tumbler screens.

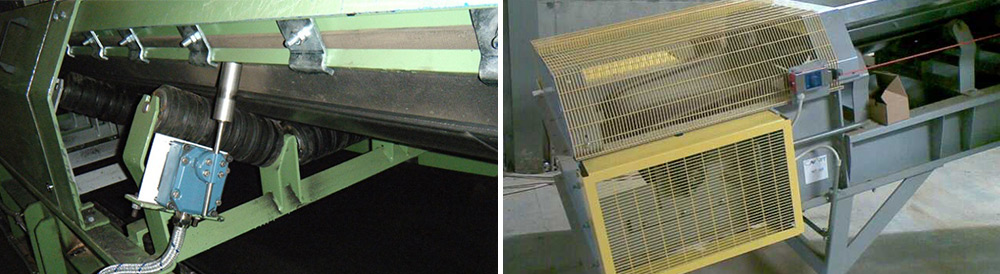

We design, build and install screening machinery equipped with all necessary accessories like support structures for conveyors and machines,

de-dusting systems if necessary, catwalks and last but not least the

connections between machines.

It is important to remember that the connections between machines play a fundamental role in the functioning of the plants.

If just one connection is not well designed the correct functioning of the entire system, in terms of productivity and reliability, is compromised.

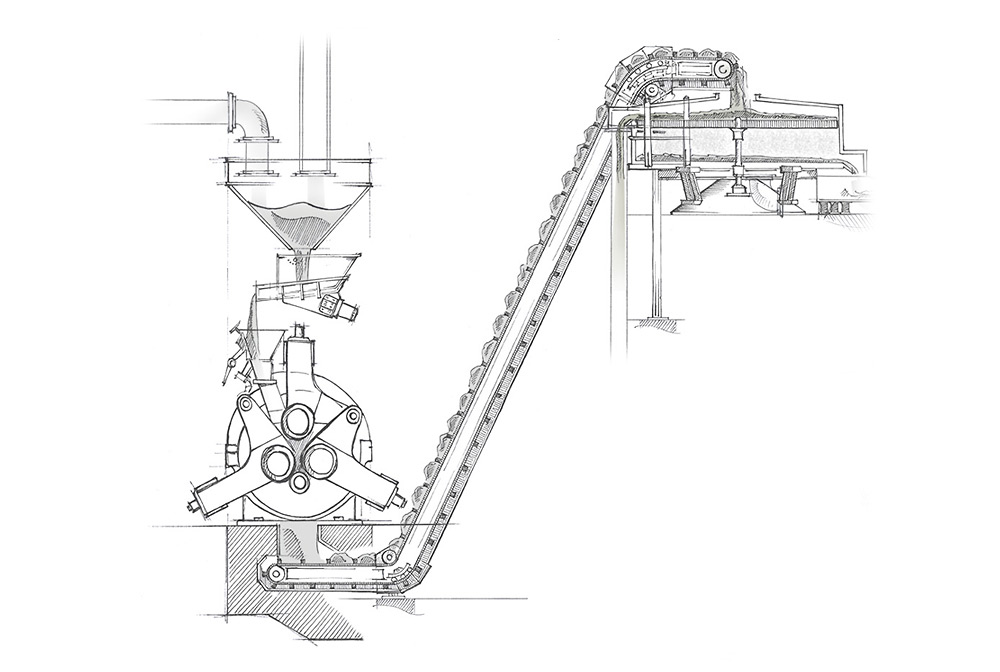

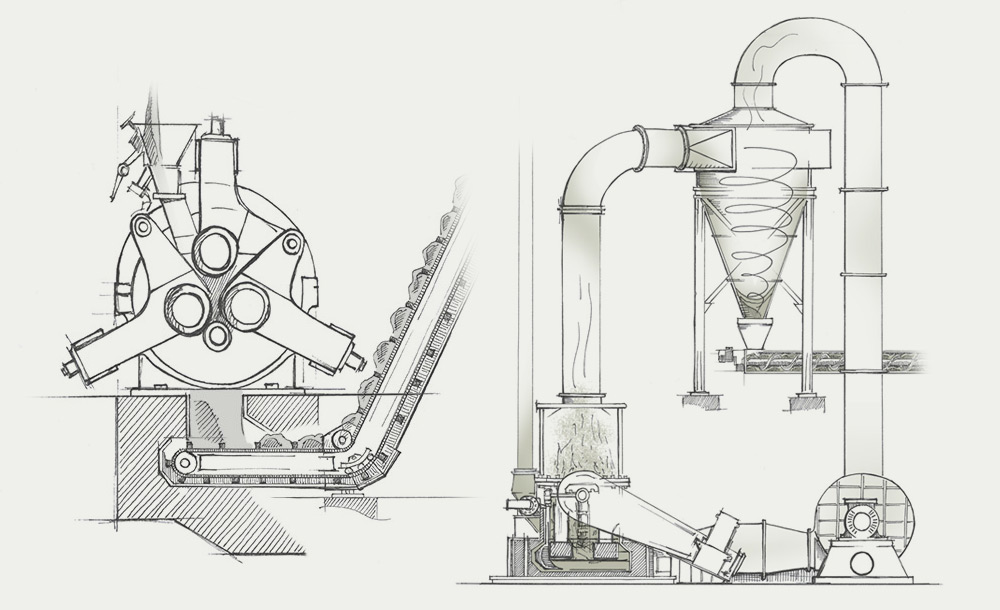

Grinding is necessary to transform inert materials into fine sands or powders.

In order to obtain sands, we employ

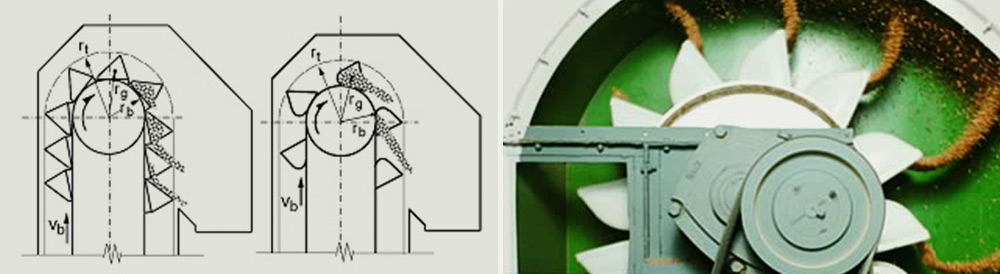

impact mills (with a horizontal or vertical axis), whereas we use

roller mills joined to wind separators to obtain powders. In the wind separators, the classifying of fine powders is carried out by an upward air stream, flowing at a controlled speed.

The air stream carries only those particles that are only a few dozen microns wide.

With

Bag filters or

cyclones we separate powders, which in this case are a product and not a pollutant, from the air stream.