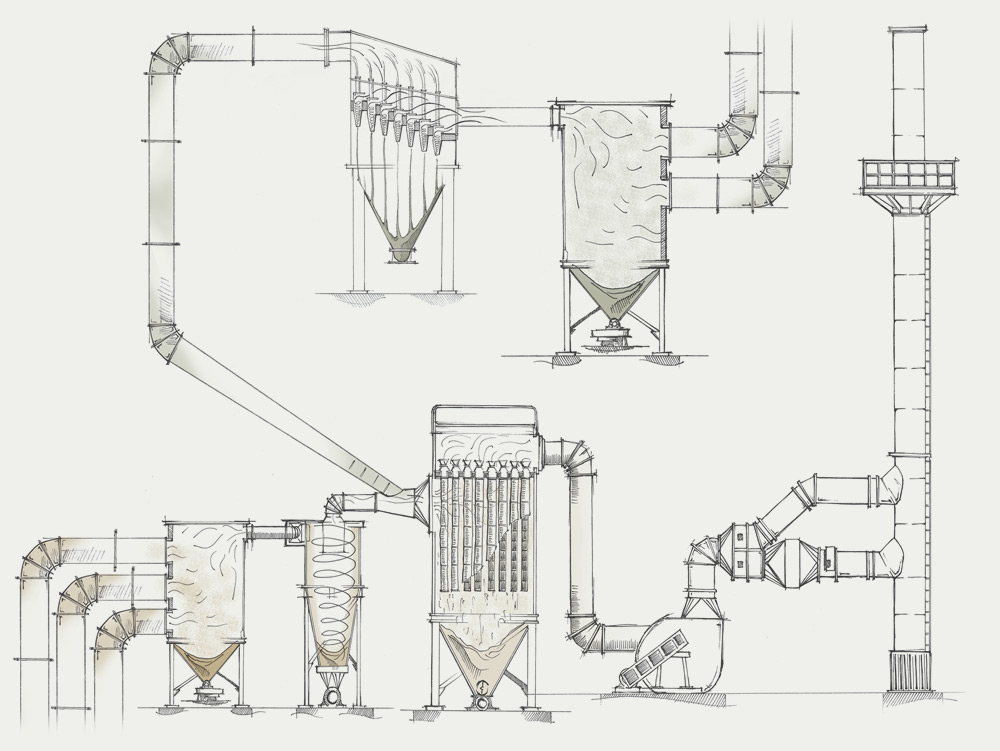

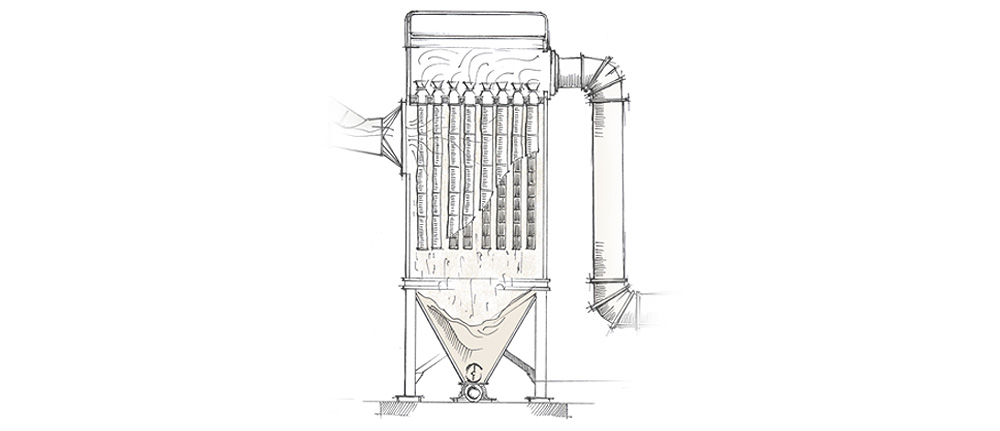

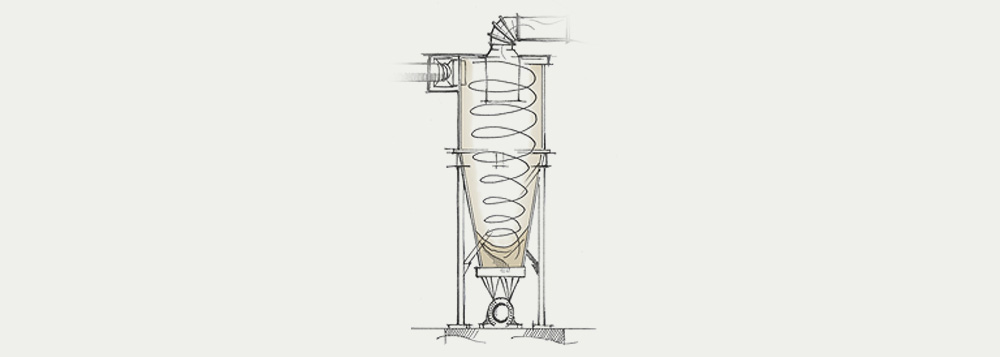

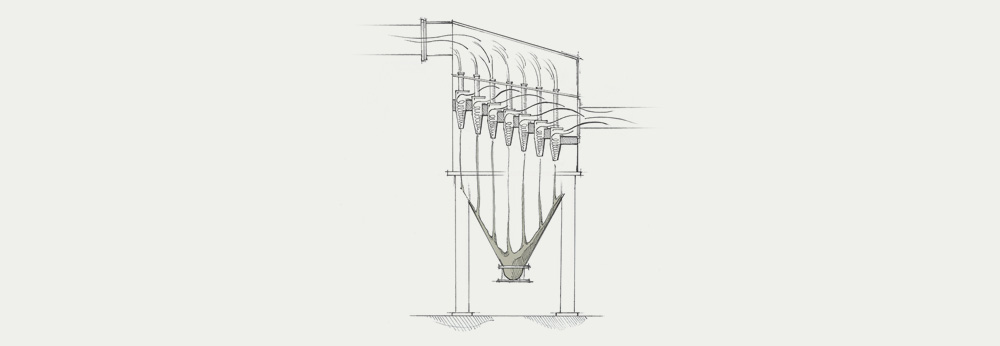

Bag filter

The

bag filters are certainly the heart of the suction and filtration system, and thus the choice of each component, from the filter media, to the equipment for counter-current washing, from the dust evacuation system to the filter shape, is fundamental for the entire system to function effectively.

Based on our experience, we choose and calculate each filter detail taking the following into account:

• The gaseous fluid (specific weight, temperature etc.) to be treated.

• The pollutant that needs to be filtered (actual specific weight, dust granulometry, dust concentration etc.).

• The chemical and physical compatibilities between the media filter and gaseous fluid to be depolluted.

• How abrasive or gluey the dust is.

• The operating temperature.

• The relative humidity of the gaseous fluid.

With the operating parameters in mind, we choose:

• Media filter type and how it is coated.

• Bag cage filter: number of wires and how it is attached to the tubesheet.

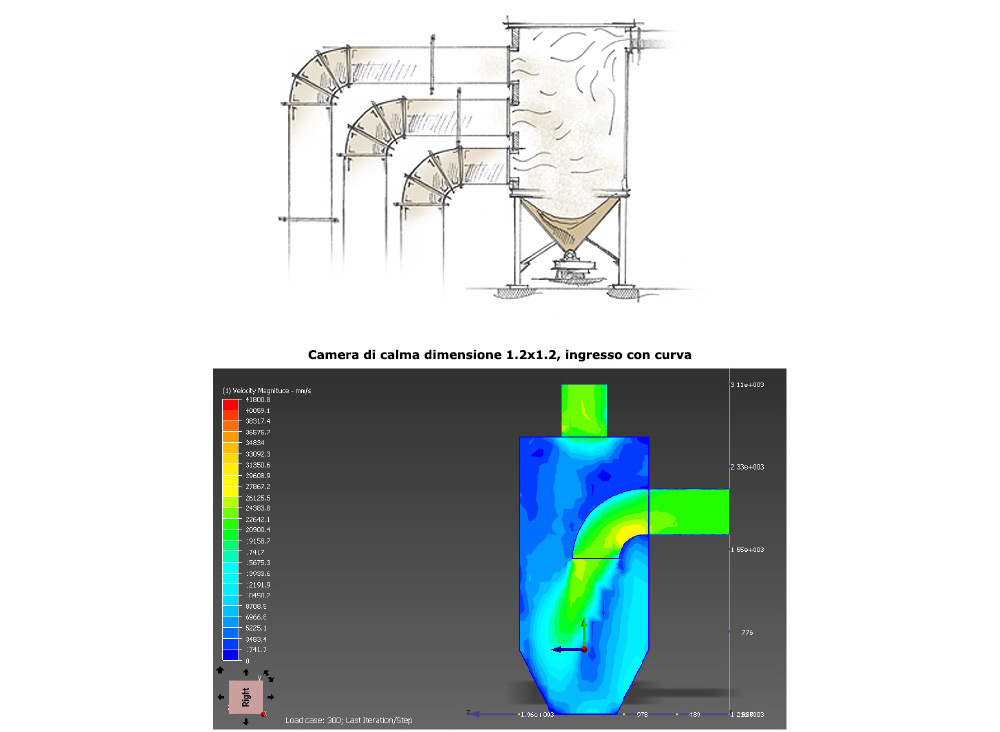

• How the gaseous fluid is admitted into the filtration chamber.

• The filter cleaning system (valves, nozzles and Venturi)

• The dust evacuation equipment ( screw, rotary valve or clapper valve)

• The preheating system for the hopper and the filtration chamber.