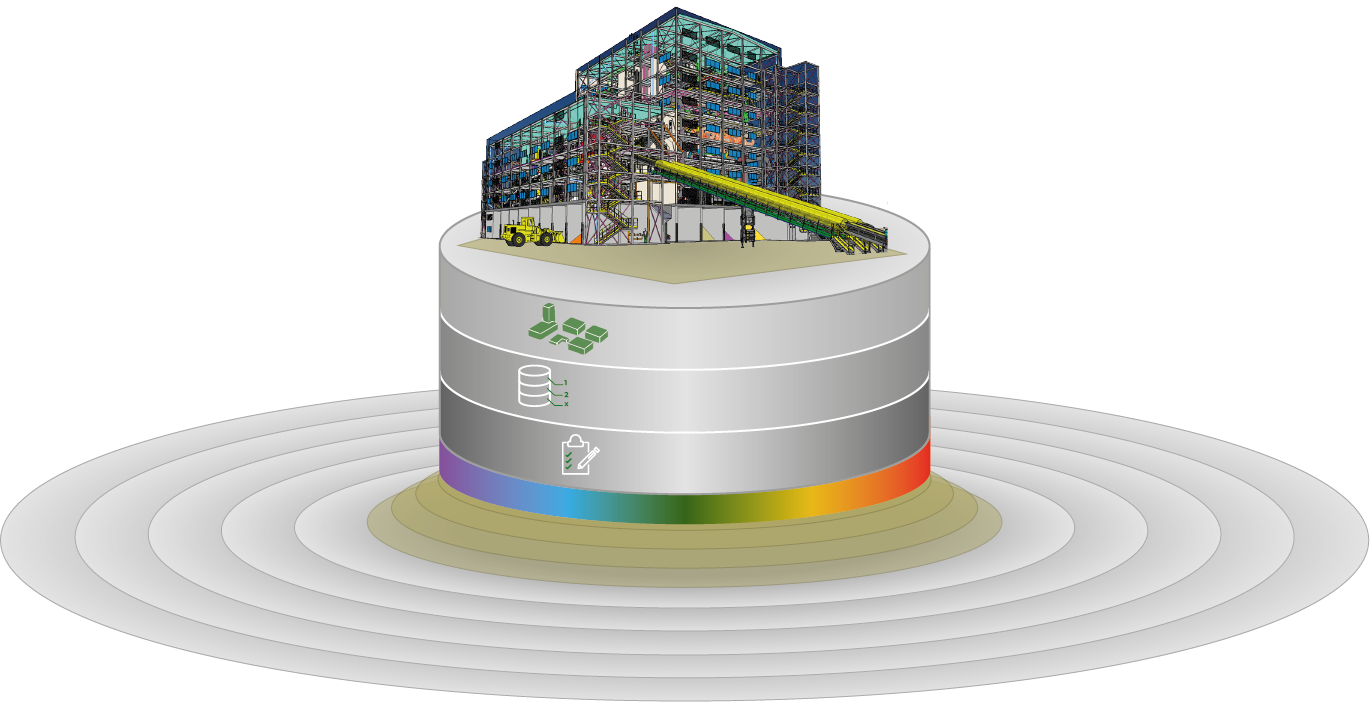

ENGINEERING SOLUTIONS

SCROLL

SCROLL

Sostenibilità CavArt

Sostenibilità CavArt